Images

Each entry below is accompanied by actual photos of the inspection.

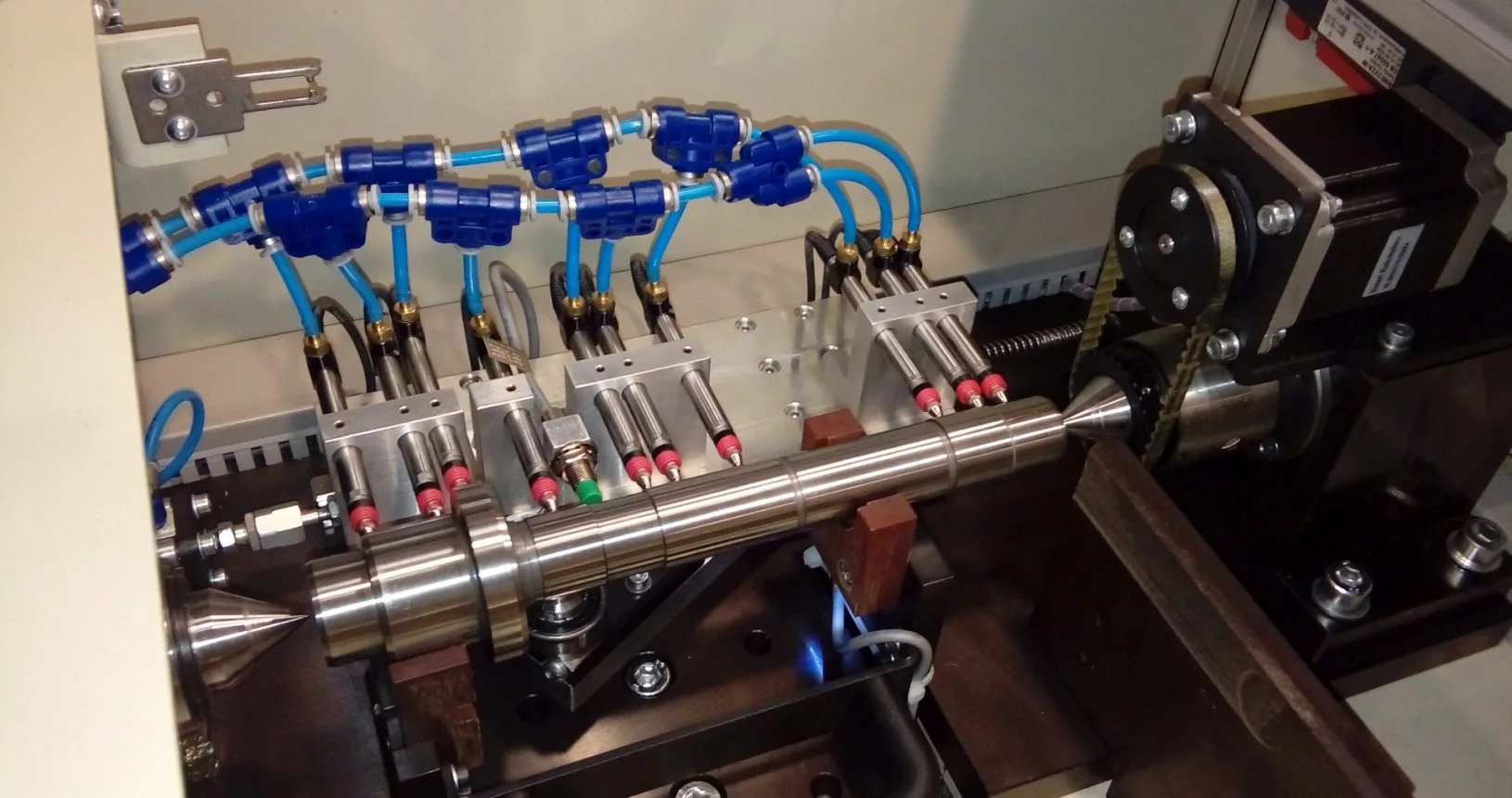

Reverse Idler Shaft

100% in-line inspection

Measured features:

- Diameter

- Runout

- Tolerance: < 10 μm

- Cycle time: approx. 40 sec

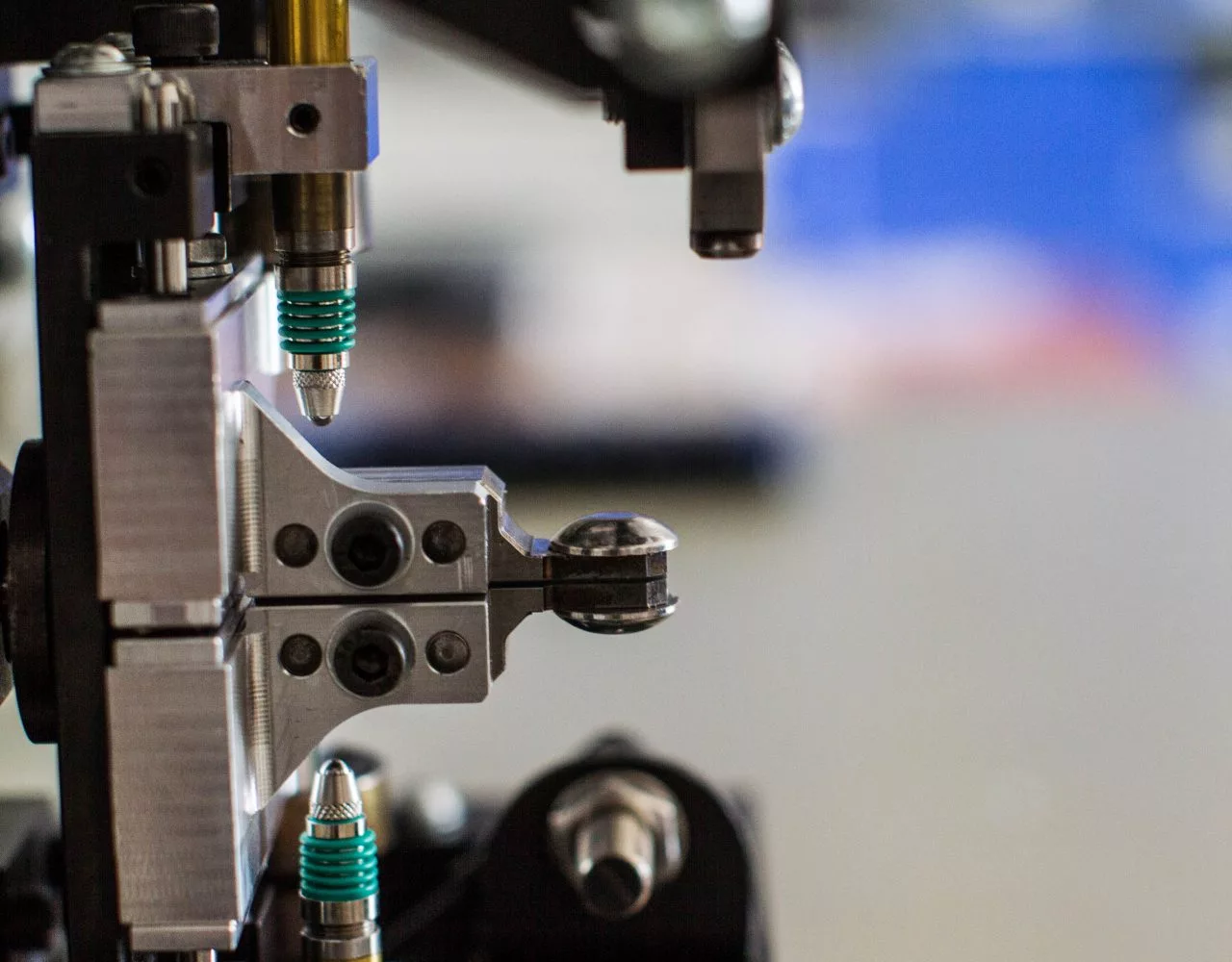

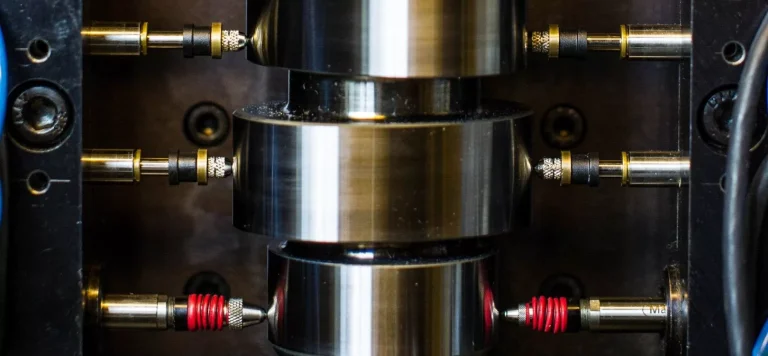

Piston Pocket Diameter

Measured features:

- Groove width

- Piston length

- Tolerance: within a few hundredths of a millimetre

- Cycle time: < 10 sec

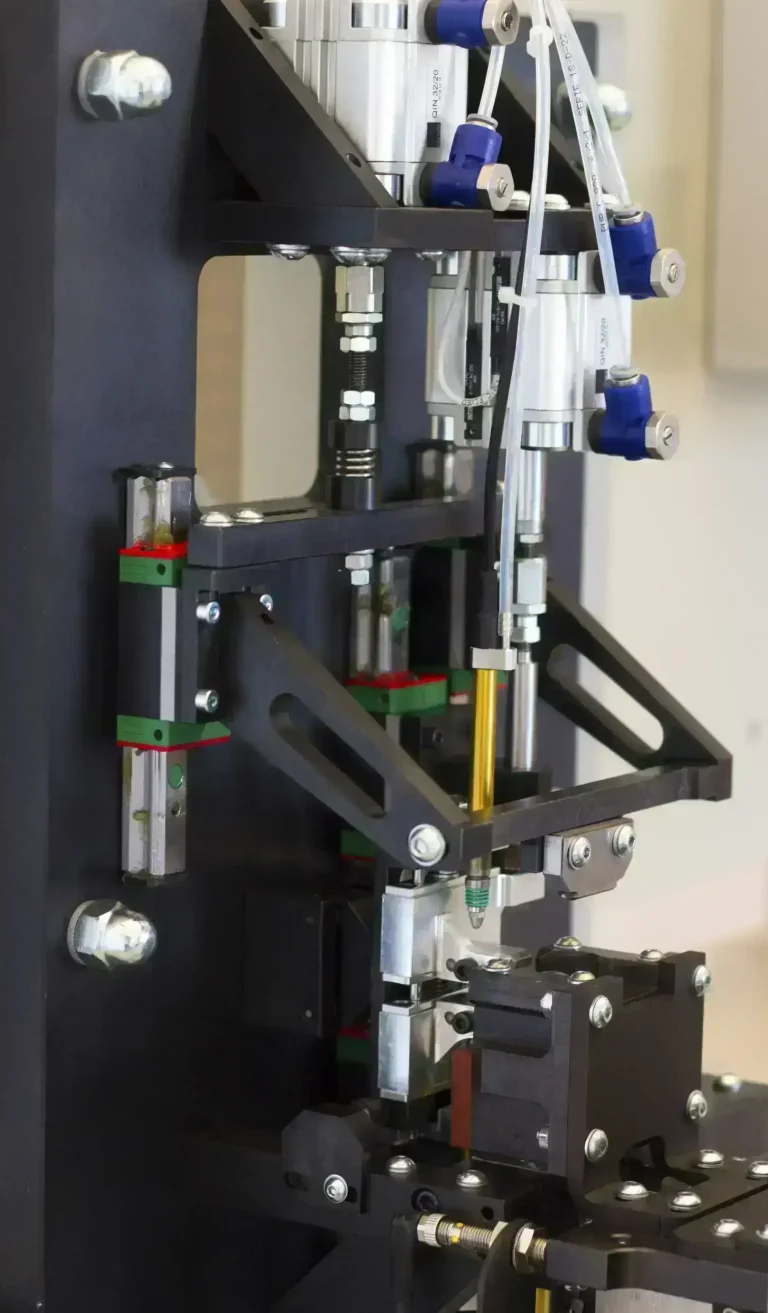

Balance Shaft

100% in-line inspection

Measured features:

- Diameter

- Balancing mass runout

- Tolerance: within a few hundredths of a millimetre

- Cycle time: < 20 sec

Camshaft Profile

100% in-line inspection

Measured features:

- Bearing surface diameter

- Cam contour profile

- Cam angular position

- Straightness and parallelism

- Tolerance: within 0.05 mm

- Two subtypes can be measured without setup change

- Three height levels measured

- Cycle time: < 150 sec

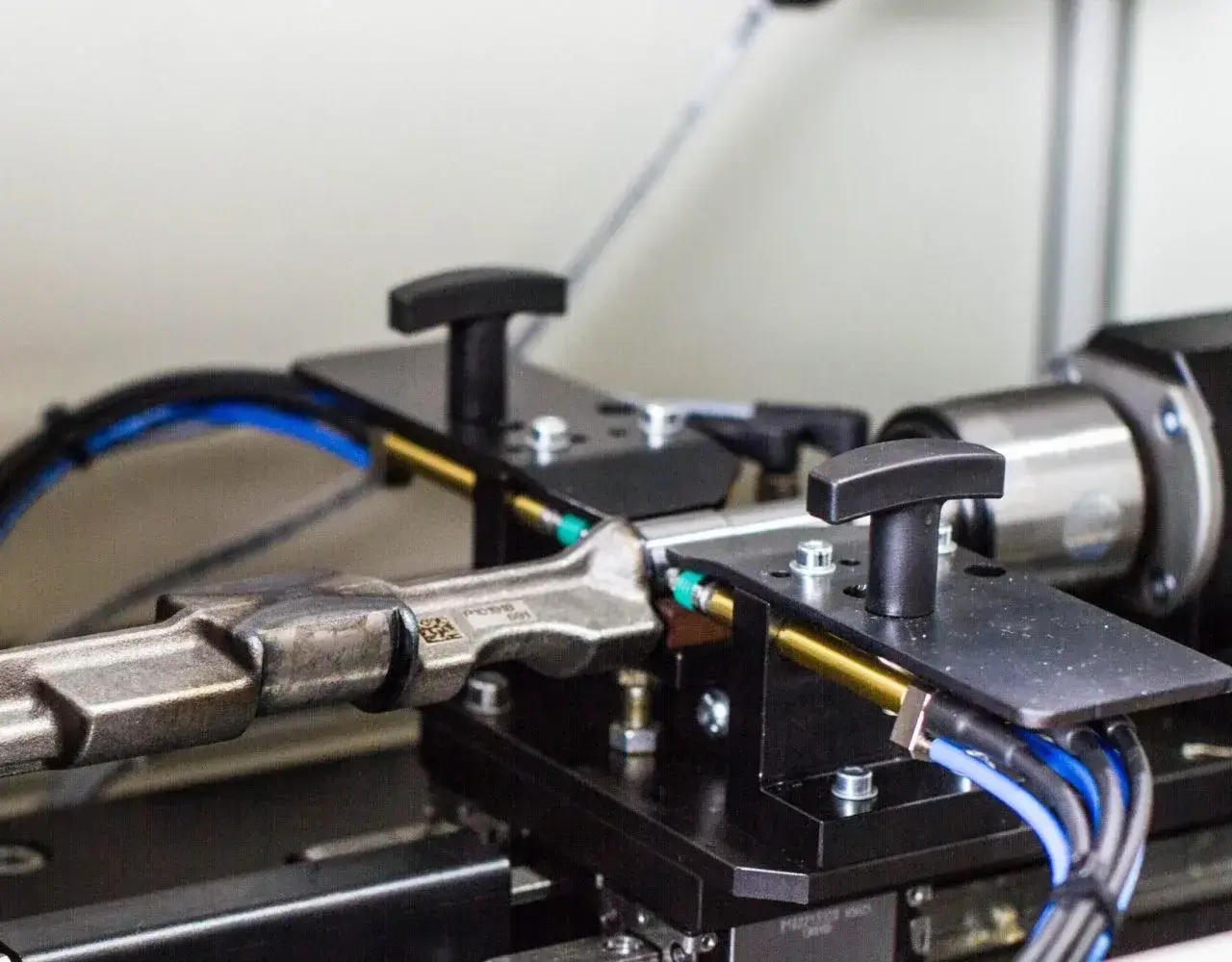

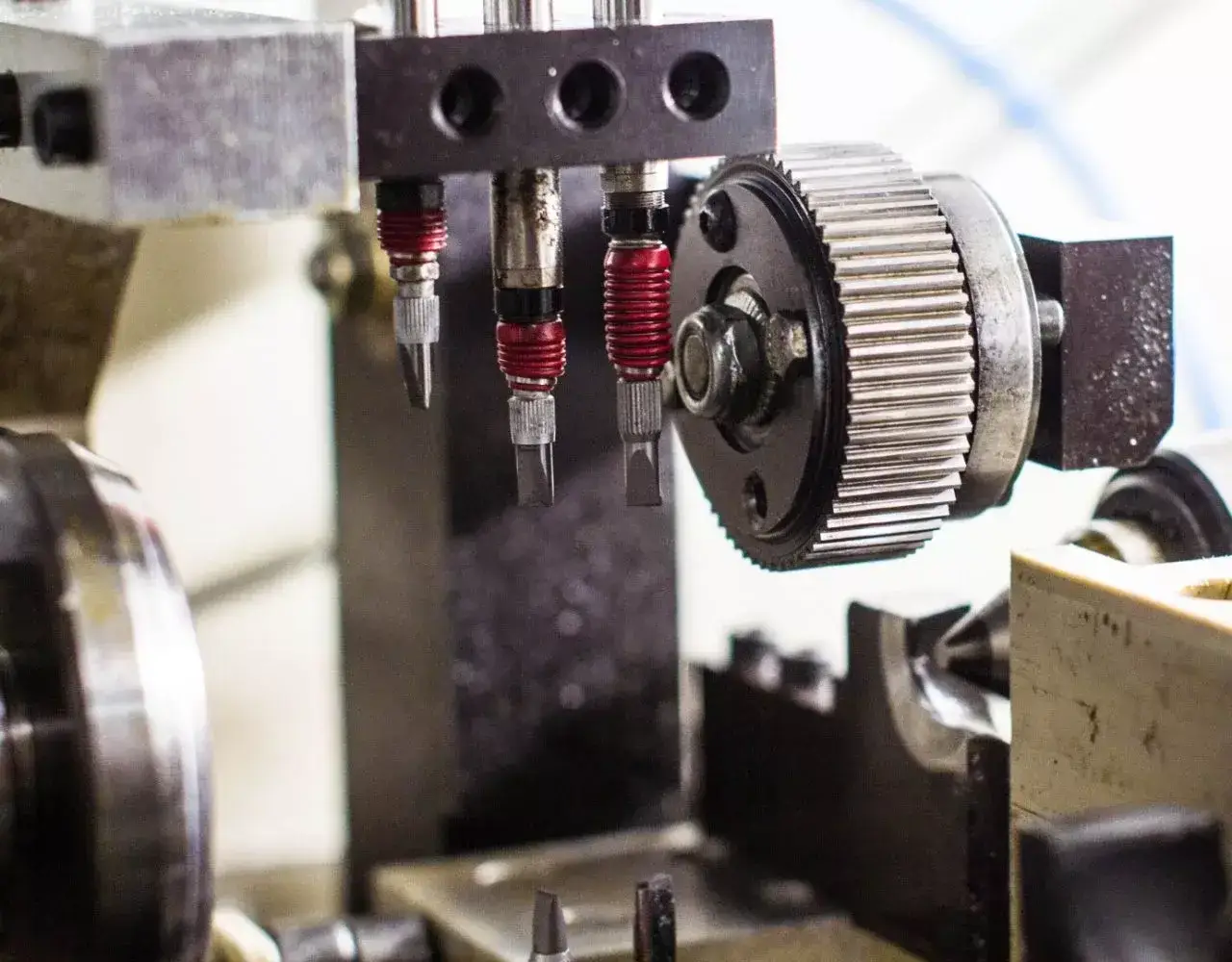

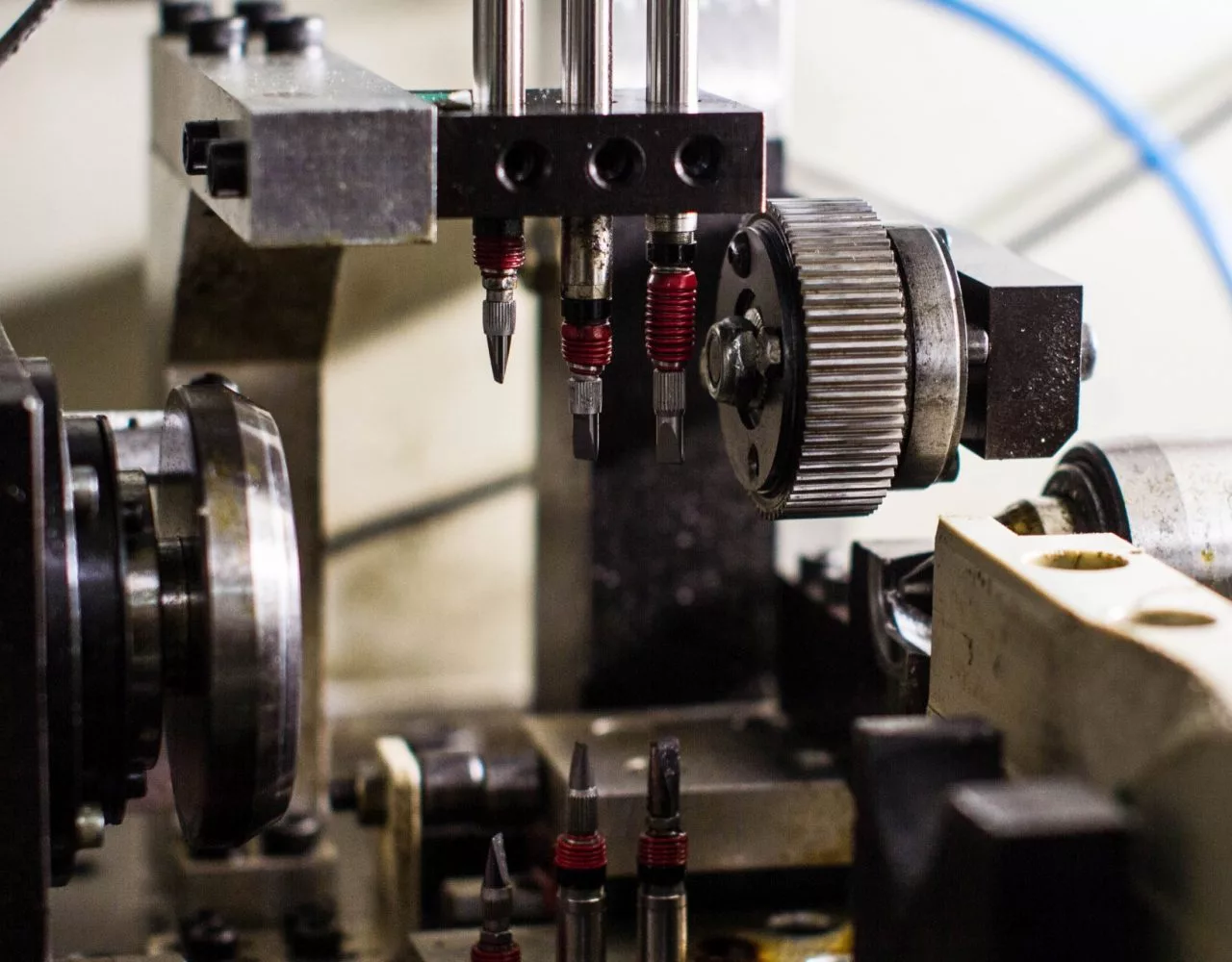

Link Shaft

100% in-line inspection

Measured features:

- Diameter

- Runout relative to bearing surfaces

- Cycle time: < 26 sec